Advancements in CNC Machining: Precision Redefined for Metal Forming

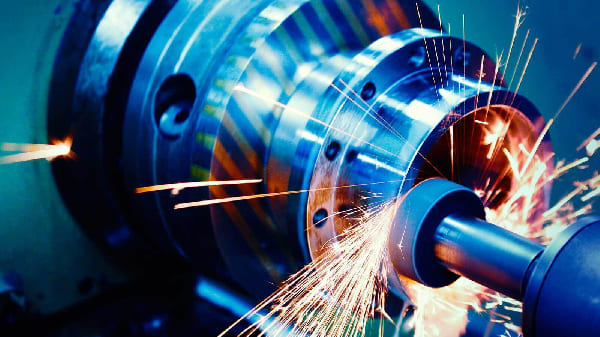

The metal forming industry is undergoing a rapid transformation, with CNC (Computer Numerical Control) machining leading the way in innovation. This highly automated process has revolutionized the production of metal components by offering unparalleled precision, repeatability, and flexibility. With the ability to manufacture intricate parts with tight tolerances, CNC machining has become an indispensable tool for industries that demand high-quality, precision-engineered components.

The global CNC machining market is expected to reach USD 128.2 billion by 2026, growing at a CAGR of 7.5% from 2021 to 2026, according to industry reports. This surge is driven by the increasing demand from sectors like aerospace, automotive, and defense where accuracy and consistency are paramount. In India, the adoption of CNC machining within the metal forming industry is accelerating as manufacturers strive to improve efficiency, reduce lead times, and meet the rising need for customized, precision components.

Benefits of CNC Machining in Metal Forming

- Unmatched Precision: CNC machining enables the production of complex parts with exact specifications, offering a level of precision that manual processes can't match.

- Efficiency and Automation: The automation in CNC machining significantly reduces the need for manual intervention, resulting in faster production cycles and consistent, high-quality output.

- Complex Geometries: With CNC technology, manufacturers can easily handle intricate designs and complex shapes, making it essential for industries that require customized components.

- Material Versatility: CNC machining works with a broad range of metals like steel, aluminum, and titanium, which are critical in sectors such as aerospace, automotive, and heavy engineering.

India's metal forming industry is expanding rapidly, driven by the demand for precision and high-quality components. As manufacturers aim to keep up with global standards, CNC machining is proving to be a pivotal technology. By streamlining manufacturing processes, reducing waste, and enhancing product quality, CNC machining is enabling Indian companies to compete on a global scale. The Metal Forming Expo, scheduled from 11-13 April 2025 at PIECC, Moshi, Pune, will showcase the latest advancements in CNC machining. Attendees will have the opportunity to experience live demonstrations, explore innovations in precision machining, engage with industry leaders, and discover how CNC technology can be integrated into their operations for superior results. Join us in Pune to display Computer Numerical Control (CNC) machining in front of industry professionals from automotive, aerospace, electronics, and heavy engineering sectors who are looking streamline their manufacturing processes.