Advancements in Laser Cutting: A Game-Changer for Metal Forming

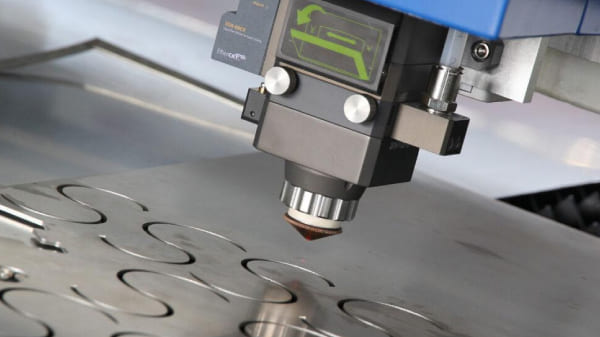

The metal forming industry has witnessed significant technological advancements over the years, and

one of the most transformative is laser cutting. This precision-driven technology is revolutionizing how

metal components are fabricated, offering unparalleled accuracy, speed, and efficiency. As industries

continue to demand more complex and precise parts, laser cutting is becoming an essential tool in the

metal forming process.

The Global Laser Cutting Machine Market is gearing up for steady growth, achieving a moderate CAGR of

5.80% through 2034. Its value is projected to climb from USD 3,776.10 million in 2024 to an impressive

USD 6,635.90 million by 2034. This growth is fueled by the increasing demand for high-quality metal

parts in industries such as automotive, aerospace, electronics, and heavy machinery.

India, with its burgeoning manufacturing sector, is no exception to this trend. The country’s metal

forming industry is increasingly integrating laser cutting technology to meet the demands of modern

manufacturing. For instance, in the automotive sector, laser cutting is used to create lightweight

components that contribute to fuel efficiency and overall vehicle performance.

Benefits of Laser Cutting in Metal Forming

- Precision and Accuracy: Laser cutting provides unmatched precision, allowing for the creation of

intricate designs and complex shapes with high levels of accuracy.

- Speed and Efficiency: Laser cutting significantly reduces production time compared to traditional

methods. It allows for faster turnaround times, making it ideal for both large-scale production and

small-batch manufacturing.

- Versatility: Laser cutting can be used on a wide range of materials, including metals like steel,

aluminum, and titanium, making it a valuable tool in various manufacturing processes.

- Cost-Effective: By minimizing material waste and reducing the need for secondary processing, laser

cutting can lower overall production costs, making it an economically viable option for

manufacturers.

As the metal forming industry continues to evolve, the adoption of advanced technologies like laser

cutting is becoming increasingly critical. The precision, efficiency, and versatility of laser cutting are

transforming manufacturing processes, enabling the production of high-quality components that meet

the stringent demands of modern industries.

The Metal Forming Expo in Pune will showcase the latest advancements in laser cutting technology,

providing industry professionals with an opportunity to explore cutting-edge solutions that can enhance

their operations. Attendees will have the chance to witness live demonstrations, engage with experts,

and discover how laser cutting can be integrated into their manufacturing processes to achieve superior

results. Join us at the upcoming Metal Forming Expo, scheduled from 11-13 April 2025, PIECC, Moshi,

Pune to showcase the latest advancements in laser cutting technology to a targeted audience of

industry professionals.